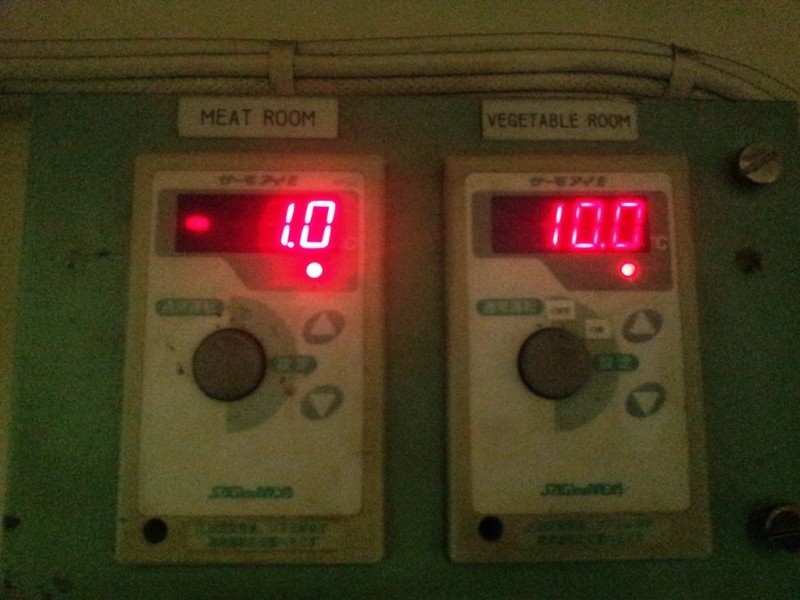

In the critical hours before midnight, a distress call reached Seaway Ship Services: a 142,000 DWT bulk carrier transiting the strategically vital Dardanelles Strait had suffered complete failure of its provision cold room refrigeration system. The vessel carried a time-sensitive cargo of 120,000 tonnes of grain destined for Black Sea ports, with strict delivery deadlines and mounting demurrage costs. More critically, the crew's food storage systems—including separate meat and vegetable cold rooms—had completely ceased operation, threatening both cargo temperature stability and crew provisions for the remaining voyage.

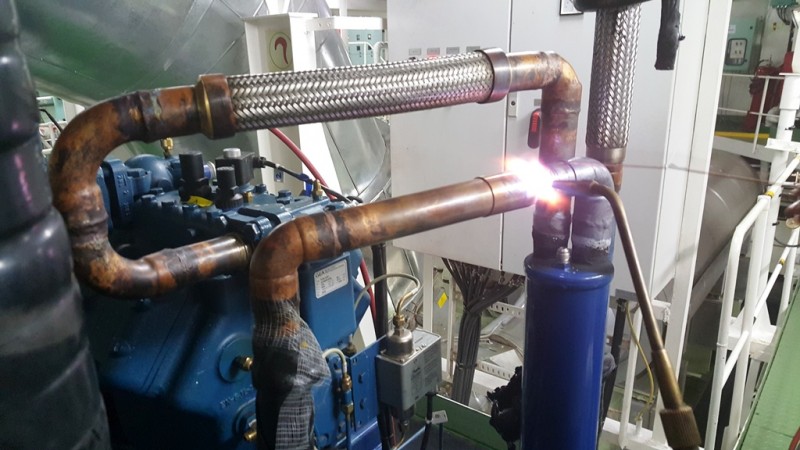

This wasn't a scenario that permitted delays for parts ordering or scheduling repair windows. The vessel's operational imperatives were clear: repairs must be completed without deviating from the planned transit route, without discharging any cargo and without causing delays that would trigger penalty clauses. Our response team mobilized two specialized refrigeration engineering units within 90 minutes, assembling a comprehensive toolkit of diagnostic equipment, refrigerant gases, precision welding apparatus, replacement compressor components and all necessary consumables for a complete system overhaul.

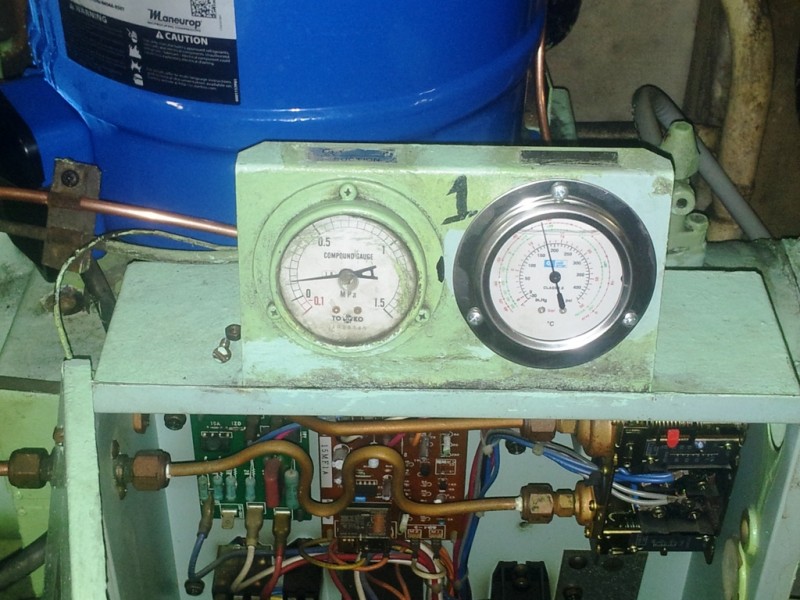

What followed was an intensive 18-hour technical intervention that would test every aspect of our refrigeration expertise. Our engineers diagnosed a cascade of failures: the primary compressor had suffered bearing seizure due to refrigerant contamination, the system had lost all R-404A refrigerant charge through multiple leak points, copper refrigerant lines showed stress fractures requiring precision welding repairs and the expansion valves had become blocked with moisture and debris. Working in cramped engine room conditions with temperatures exceeding 40°C, our teams executed simultaneous repairs across two cold room systems while the vessel maintained its transit schedule through one of the world's most congested maritime chokepoints.